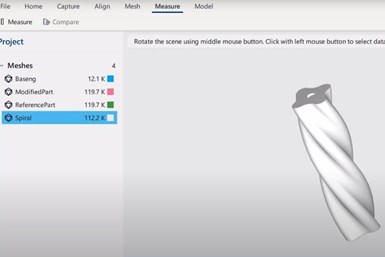

Faro RevEng Software Reverse-Engineers CAD Surfaces

Software is designed to generate a high-quality mesh and quickly produce exportable CAD surfaces for machining, finite element analysis simulations or 3D modeling.

Edited byAngela Osborne

Faro’s RevEng Software 2021

Faro’sRevEng Software 2021 features automatic surfacing capabilities for creating surfaces quickly directly from scanned point clouds and meshes. Its auto surfacing capabilities are designed to help create fast, high-quality CAD surfaces.

RevEng is designed to be an affordable and fast reverse engineering scan-to-CAD softwaresolution that helps users reduce data capture time and eliminate overlapping data points. The software is said to be well suited for aftermarket design, creation of replacement parts, new design iterations or additive manufacturing.

The automatic NURBS (Non-Uniform Rational B-Spline) surfaces creation tool enables the creation of a full network of curves and surface patches with the click of a button, ready for immediate export into a CAD file, the company says. Full control is also said to be possible by customizing the surface patches in the sketch mode with a flexible control point placement, while curves are color coded to quickly verify surface continuity. The 3D point cloud capture enables users to create models up to 1.75 times lighter with a grid management feature to obtain clean, light and consistent point cloud data.

The software is designed to make reverse engineering easier and faster. Users can scan with a Faro ScanArm — paired with the optional 8-axis rotating platform to increase acquisition speed — to generate a high-quality mesh and quickly produce exportable CAD surfaces for machining, finite element analysis simulations or 3D modeling.

The company says users can also import point cloud or mesh files from any source and repair the mesh with RevEng optimization tools, automatically repairing meshes up to 20 times faster than many other tools and improving smoothing effectiveness up to 1½ times faster. This makes RevEng software agnostic and can be paired with any inspection program — even for customers working with other software products.

RELATED CONTENT

Integrated Tool Management with CAD/CAM Connection

Better organization in a shop usually leads to higher productivity, and often, improved quality. That’s the objective of this modular tool data management software as it consolidates resources to encompass all aspects of production resource management.

CAM Selection Criteria For Your Swiss-type

Programming complex Swiss-type lathes is simplified with a good CAM purchase. Here are some questions you should ask your vendor.

Software Simplifies Turn-Mill Operations

An international player in the highly competitive aeronautics, automotive, defense and optical industries makes the most of software for multitasking program verification and optimization.