Genturn SL-42Y2 Swiss-type机部分大小Versatility

Appears in Print as:'Swiss-type Machine for Part Size Versatility'

瑞士型机器具有可拆卸导向衬套的灵活性,可实现4至42毫米的一系列零件尺寸。

Edited byAngela Osborne

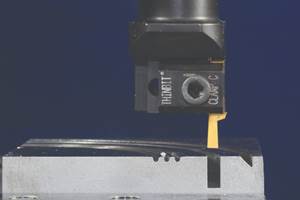

There are 33 tool positions and 13 driven tools provided as standard in the basic Genturn SL-42Y2 Swiss-type machine. Photo Credit: Expand Machinery

Expand Machinery’s8-axis Genturn SL-42Y2 hybridSwissmachine was designed to handle a range of part sizes from 4 to 42 mm. It can machine parts as small as 4 mm using a guide bushing and can also run larger work without a guide bushing up to 1-5/8" diameter — all in the same machine for a complete part in just one operation.

拥有两个独立的Y轴可以同时主导和亚板灯机效率,并提供额外的工具可能性。有33个工具位置和13个驱动工具作为标准的基本机器提供,包括13个驱动工具和13个后备工具位置,以使用户能够完成复杂的部件。

The main spindle features 20 tools that include six live crossworking driven tools and three axial live tools, six turning tool stations and five ID tool stations. The five ID tool stations can also utilize dual insert toolholders to further increase the total tool count. The subspindle has 13 tool stations, including four driven stations with four live toolholders as well as and four ID tool positions. An option of up to four additional driven tools can be inserted into the subspindle tool block as needed for a maximum of eight driven tools.

The backside of the five ID tool stations on the main tool bridge can be utilized on the subspindle as required. Both the main spindle and the subspindle have a high-performance, C-axis with full contouring with 360,000 radial positions (0.0001-degree resolution) to facilitate engraving and detailed milling requirements.

The main spindle uses a 10-hp motor driving a 6,000-rpm spindle that uses a Traub A-42 collet. The subspindle uses a 6-hp motor to drive the 6,000-rpm subspindle. The maximum cut length using a guide bushing is 12.6". The one-piece, heavy-duty box-style machine bed and base casting is made of a high-density Meehanite processed cast iron that is heavily ribbed to increase lateral stiffness and maximize stress absorption during the machining process.

相关内容

Moving Up To CNC Swiss Screw Machines

Three new CNC Swiss machines in 18 months have provided real growth for this Illinois shop.

Racing to High Tech Turning

赛车组件制造商获得更高的RPM,更快的速度以及具有新阵容的车削机的复杂控制。

如何从瑞士型和多任务机器获得更高效的生产

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.