Cobot's Seventh Axis Enhances Maneuverability

是一个轻量级indu Kassow KR810从机器人strial cobot designed for speed and strength with fewer safety restrictions.

Edited by

Kassow Robotshas launched theKR810, a lightweight industrial cobot designed for speed, strength and maneuverability. The company says the cobot requires fewer safety restrictions, making it suitable for working alongside humans in industrial applications such as machine tending, assembly and limited-space retrofits. According to Kassow, it designed the robot to improve payload, cycle times, reach and flexibility.

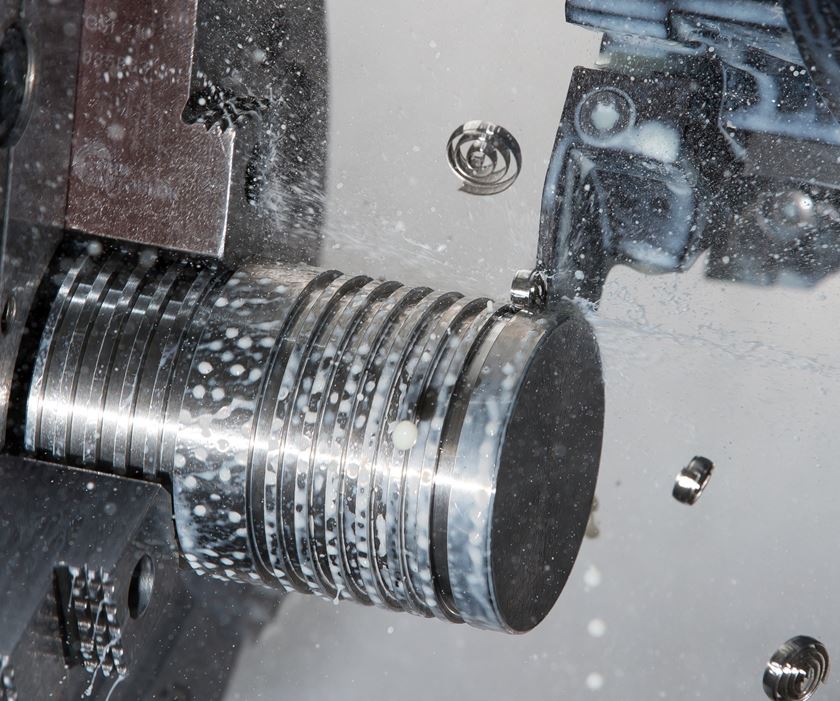

The KR810 features a payload of 10 kg and a reach of 850 mm. It features a seventh axis, or “wrist” joint, that promotes maneuverability. Work cell designers can place the cobot to the side of an opening, leaving space for users to access CNC systems, lathes, injection molds and related machinery. Users of all technical expertise levels can program the KR810, Kassow says. The robot is programmed by moving it into position and recording the key points. The Kassow software does the rest.

According to the company, this solution is well suited to small- and medium-sized companies looking to implement or expand cobot solutions.

RELATED CONTENT

Choosing an Automatic Bar Feeder

The bar feeder is the most common form of automation for turning operations. Selecting the right one requires consideration of the applications for which it will be used.

The Many Sides of Workholding

Here's a broad look at different ways to approach workholding, from bar feeders to collet chucks to robotics.

Advantages of Cellular Manufacturing

Manufacturing cells are used to minimize product movement as well as materials, equipment and labor during the manufacturing process. By reducing cycle times and material handling, these cells help shops more easily meet customer demands regarding cost, quality and leadtimes.

.JPG;width=70;height=70;mode=crop)